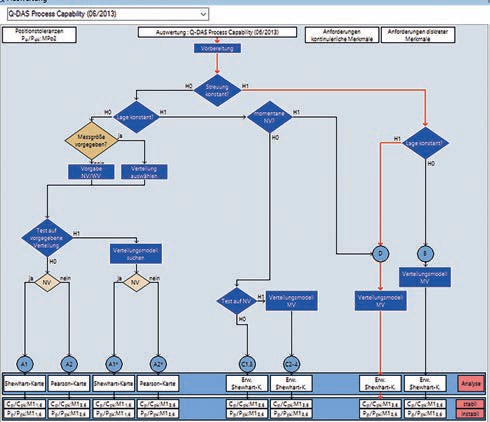

AUTOMATED EVALUATION THROUGH EVALUATION STRATEGIES

There are different requirements and methods regarding the calculation of statistics

like Cp and Cpk values. All of them are either based on standards, association and corporate

guidelines (e.g. BMW, GMPT, Robert Bosch, Volkswagen etc.) or an individual approach.

The evaluation strategy defines all the specifications required to calculate statistics.

At the heart of Q-DAS software products, this strategy guarantees the reproducibility of results.

• Applying the integrated evaluation strategy, users always follow the correct approach to the calculation of statistics based on standards, association and corporate guidelines or an individual procedure

.• Results become comparable and can be validated.

• Q-DAS qs-STAT creates confidence in the reliability of results.

• Due to the option to adapt the evaluation strategy to specific requirements, users are able to satisfy individual demands

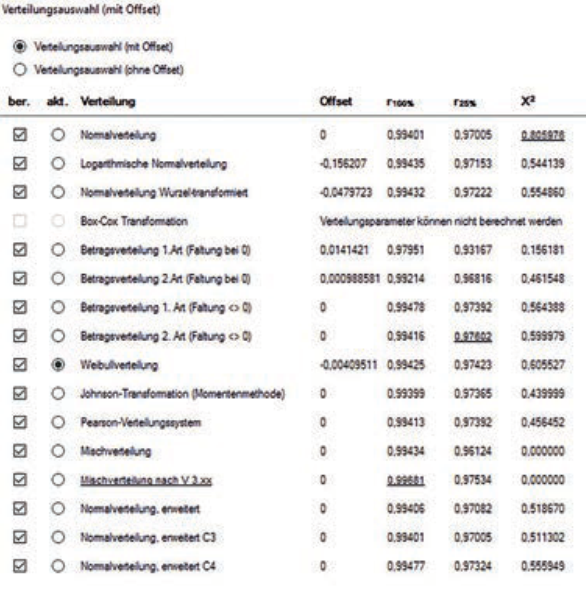

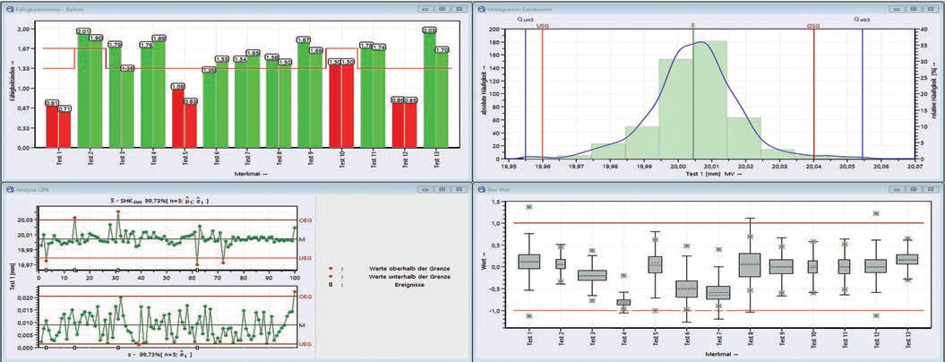

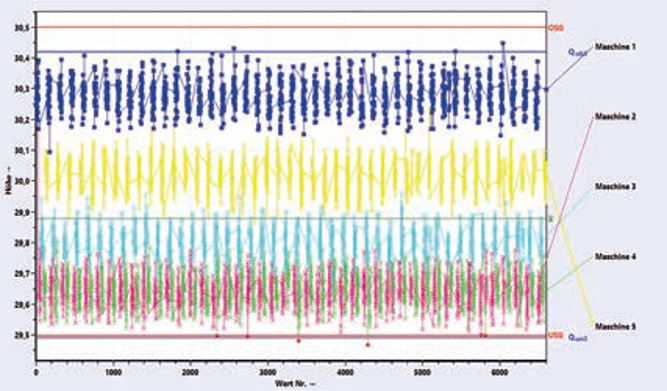

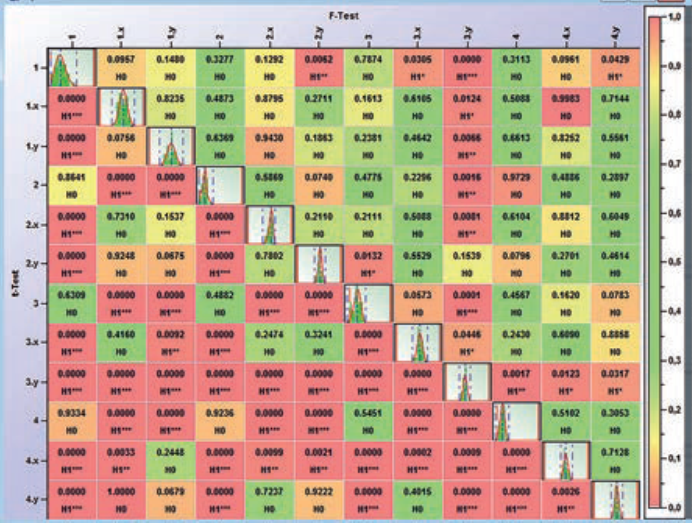

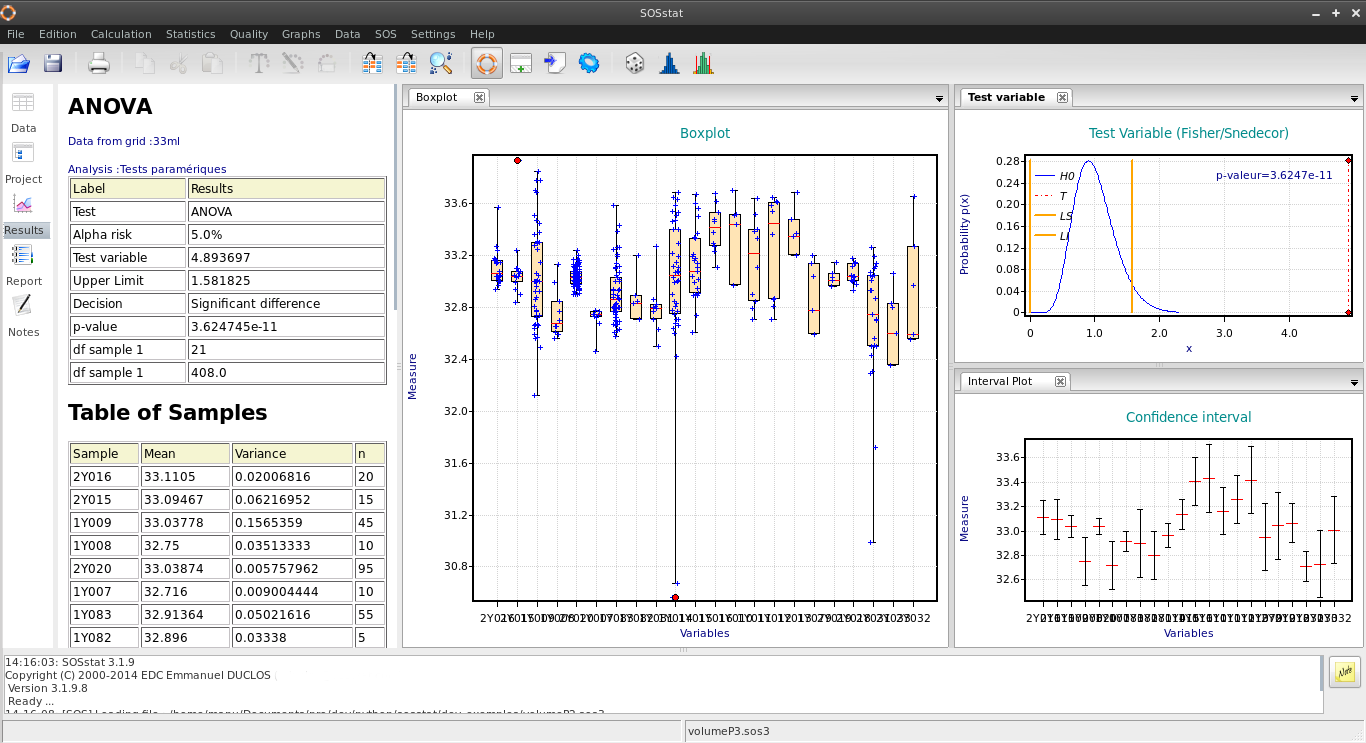

GRAPHICS AND STATISTICS

There are numerous statistical procedures available identifying the best suitable distribution time model automatically

and assigning the data to the respective process model as given in ISO 21747-2. Q-DAS qs-STAT also provides users with a

rich set of statistical summary graphics and graphics of individuals for the visual evaluation of processes.

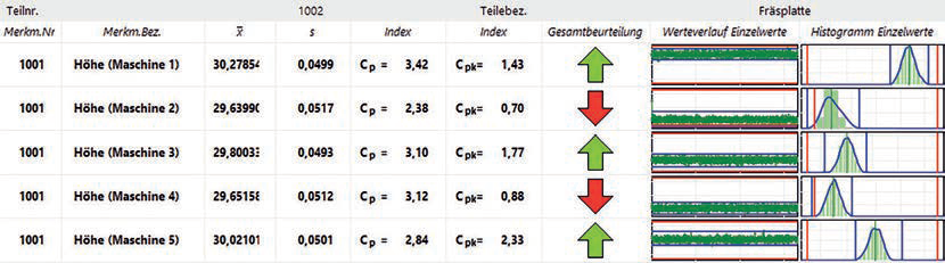

Q-DAS qs-STAT DRIVES KNOWLEDGE ACQUISITION

Q-DAS qs-STAT is recognised as a secure means for establishing machine performance and process capability. Different

filters and selection criteria detect trends and deviations. These types of analyses frequently allow users to reach

conclusions about significant influences caused by different factors like machine, batch, cavity, operator, tool,

temperature, etc. Q-DAS qs-STAT provides an essential tool for displaying influences in appealing graphics and for evaluating

them in order to identify room for improvement. The knowledge acquired leads to substantial process improvements

and reduces process costs.

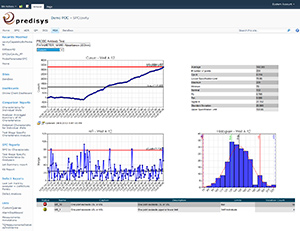

REPORTS

Reports provide users with a concise and appealing overview of statistics and graphics.

They can be stored as PDF files or sent as an email attachment. Reports used as graphic

files are easy to integrate into third-party systems.

INDIVIDUAL SETTINGS

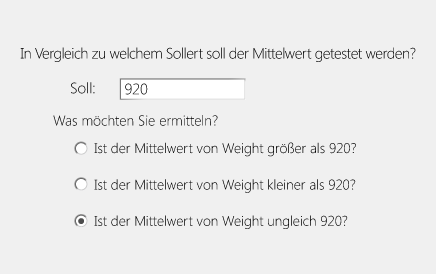

Even though Q-DAS qs-STAT focuses on the idea of an evaluation strategy,

users are still able to select statistical test procedures and individual

specifications.An individual user management supports customised

configurations specifying user rights, graphical user interfaces and

graphics settings. Approved as an easy-to-use software, Q-DAS qs-STAT

provides automated results as well as reports and offers all functionalities

and details an expert in statistics needs.

Hexagon Manufacturing Intelligence helps industrial manufacturers develop the disruptive technologies of today and the life-changing products of tomorrow. As a leading metrology and manufacturing solution specialist, our expertise in sensing, thinking and acting – the collection, analysis and active use of measurement data – gives our customers the confidence to increase production speed and accelerate productivity while enhancing product quality.Through a network of local service centres, production facilities and commercial operations across five continents, we are shaping smart change in manufacturing to build a world where quality drives productivity. For more information, visit HexagonMI.com.Hexagon Manufacturing Intelligence is part of Hexagon (Nasdaq Stockholm: HEXA B; hexagon.com), a leading global provider of information technologies that drive quality and productivity across geospatial and industrial enterprise applications.

For more informations - see links: